Wire rod

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

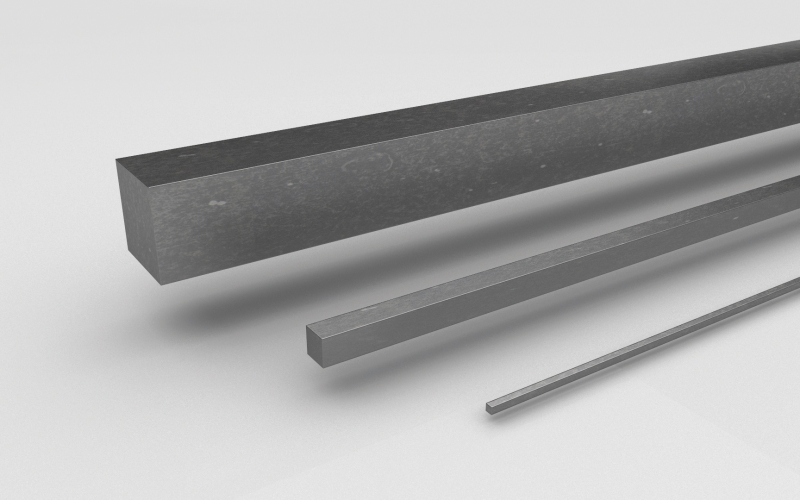

Hot rolled bars

Production takes place in a rolling mill at a controlled temperature using the very latest technology which guarantees a fine grain and homogeneous structure; the calibrator finishing block allows bars with restricted dimensional tolerances.

Production takes place in a rolling mill at a controlled temperature using the very latest technology which guarantees a fine grain and homogeneous structure; the calibrator finishing block allows bars with restricted dimensional tolerances.

Hot rolled round bars

Hot rolled square bars

Hot rolled flat bars

Hot rolled billets

Hot rolled billets in square section with radius corner (equal to approx. 15% of the side) and destined to hot forging operations.

Hot rolled billets in square section with radius corner (equal to approx. 15% of the side) and destined to hot forging operations.

Sales: ORI Martin S.p.A.

Wire rod

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Hot rolled bars

Production takes place in a rolling mill at a controlled temperature using the very latest technology which guarantees a fine grain and homogeneous structure; the calibrator finishing block allows bars with restricted dimensional tolerances.

Production takes place in a rolling mill at a controlled temperature using the very latest technology which guarantees a fine grain and homogeneous structure; the calibrator finishing block allows bars with restricted dimensional tolerances.